Square Bottom paper bag machinery it has the advantages of fast making, high production efficiency, large adjustment range, comprehensive domestic inadequate of similar Square bottom paper bag making machine products, then toimprove the new machine.

Process flow chart of paper bag :

Coiling → feeding → laminating → gluing in the middle seam → forming → conveying offset paper → gluing the offset paper → wrapping the offset paper with multi-layer paper → multi-layer forming → multi-layer traction → cutting (fixed length) → breaking → photoelectric counting → whole bag output → paper bag finished product.

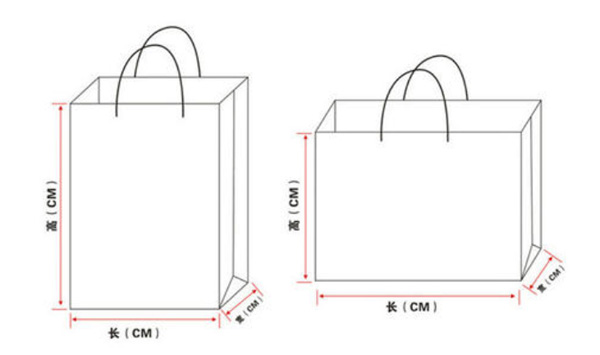

Specification of paper bag

This machine make the primary color or printed roll paper to glue on the side, folded into a tube, glue on the bottom, bag bottom forming and export bags.

The machine is controlled by computer central control system, touch screen display, the servo motor control the length of paper bags, it can produce a variety of sizes paper bags, the fastest can reach to 220PCS/Min paper bags, Square bottom paper bag making machine greatly reducing the labor costs.

paper bag machine is the best choice for producing sguare bottom paper bags.

For more information about paper bag machine, please consult our technicians